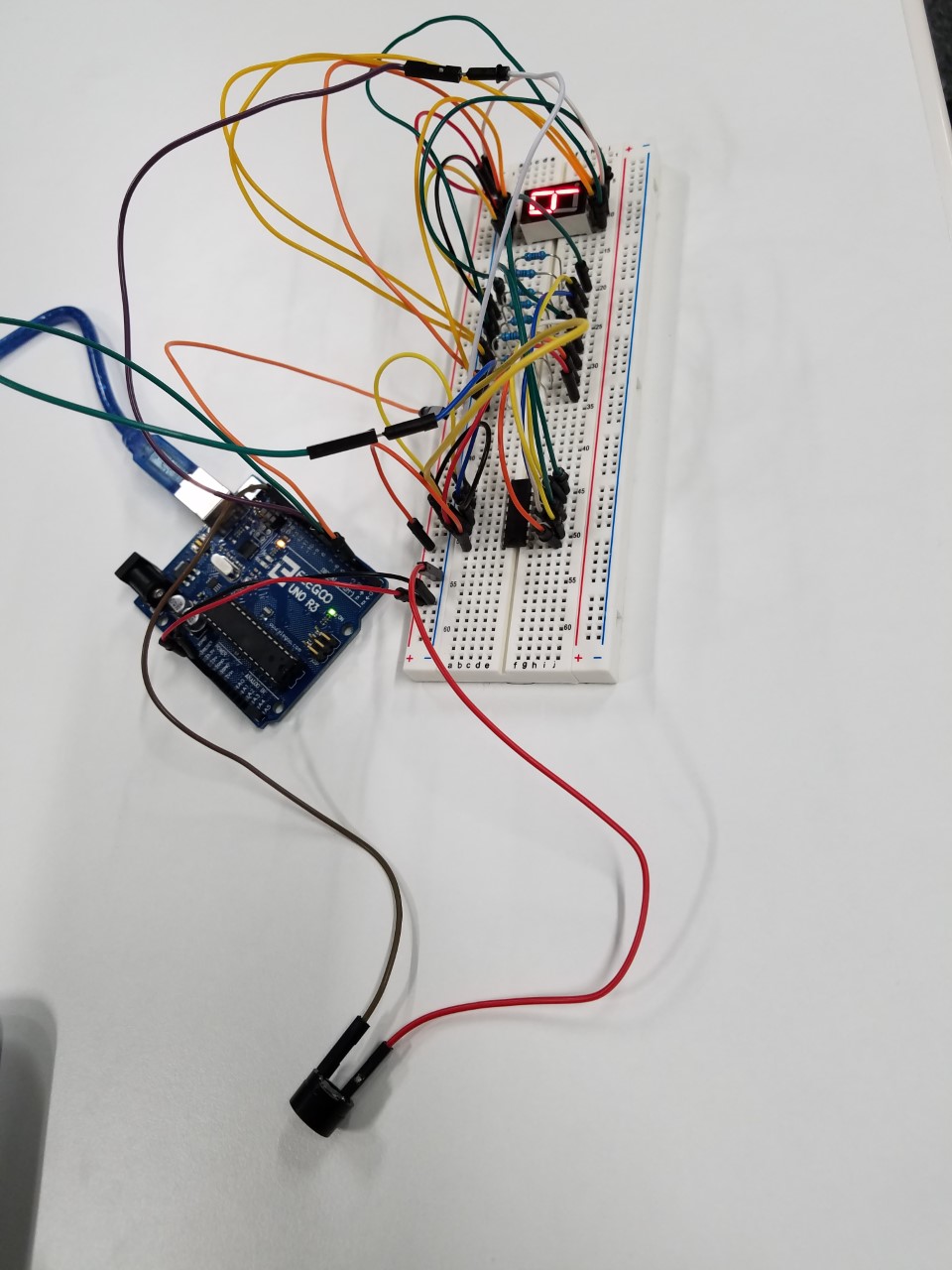

Component used:

- Elegoo UNO R3

- Ultrasonic Sensor

- LCD 1602 Module

- Breadboard

- F-M wire

- M-M wire

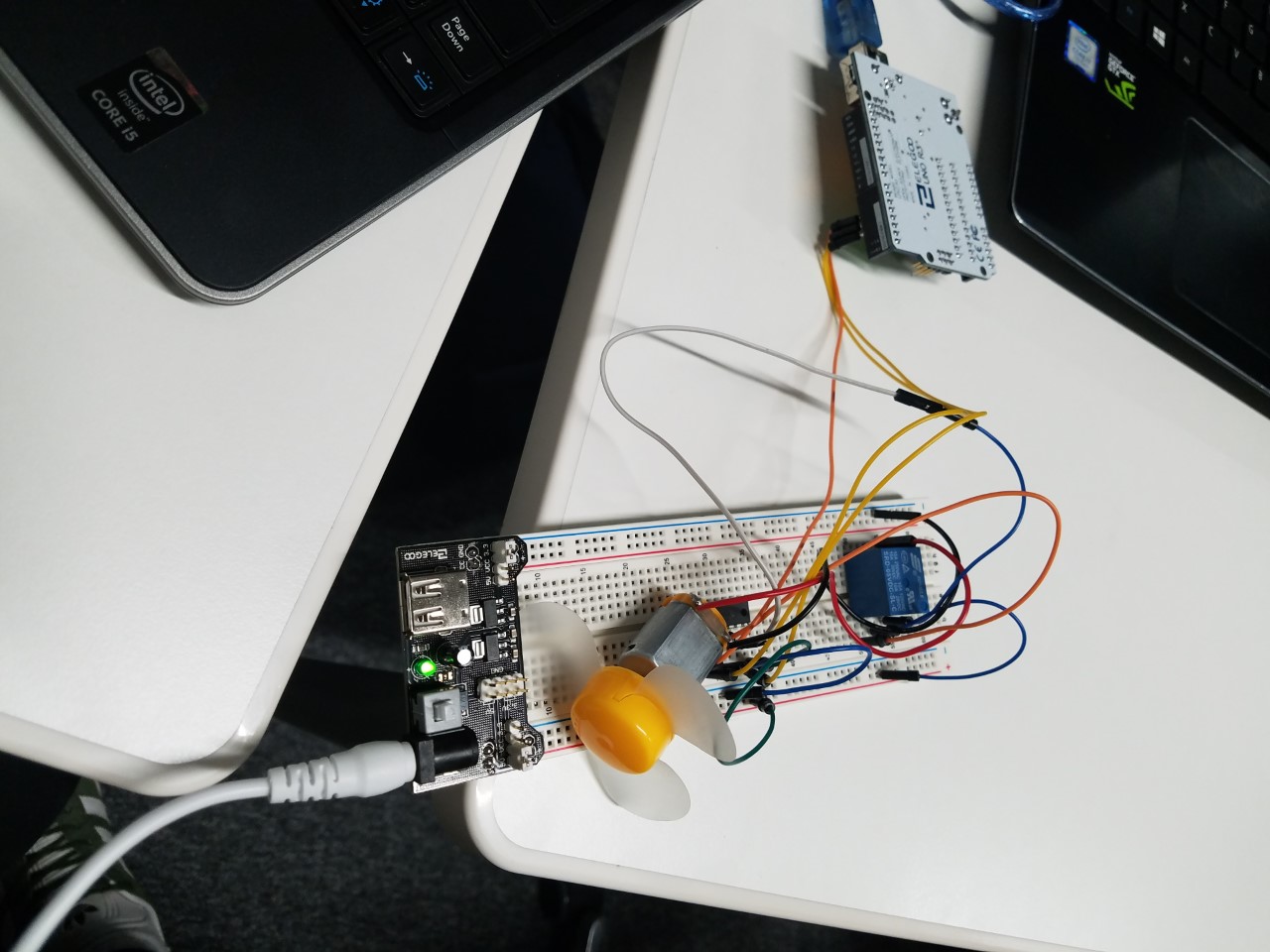

The aim of this project is to build a processor-based pet feeding system with Arduino. This system would be referred to as the “feeder”. The feeder is suitable for pet owners who leave their pets at home for long periods unattended. The objective is to feed a pet within regular intervals without the physical presence of the owner.

The features of the feeder includes a sensor which has has a proximity of 100cm. It is activated when the pet is in proximity and then automatically deactivated for a few hours to prevent multiple dispensation. This is a control feature and therefore regulates the number of times the pet feeds in a day.

An LCD screen is fitted to the breadboard and it displays a counter which records the number of times the pet was fed in a day. It is a meagre requirement however, it is useful to have statistics on the number of times the pet was fed. If the pet were to be avoid meals the entire day it could be an indication of illness or even death.

The time module (DS3232 RTC) is attached to the breadboard to implement the time and date. This is specifically for record purposes. It is a minuscule addition to the feeder system but it is helpful to know the days which had higher peak levels than others.

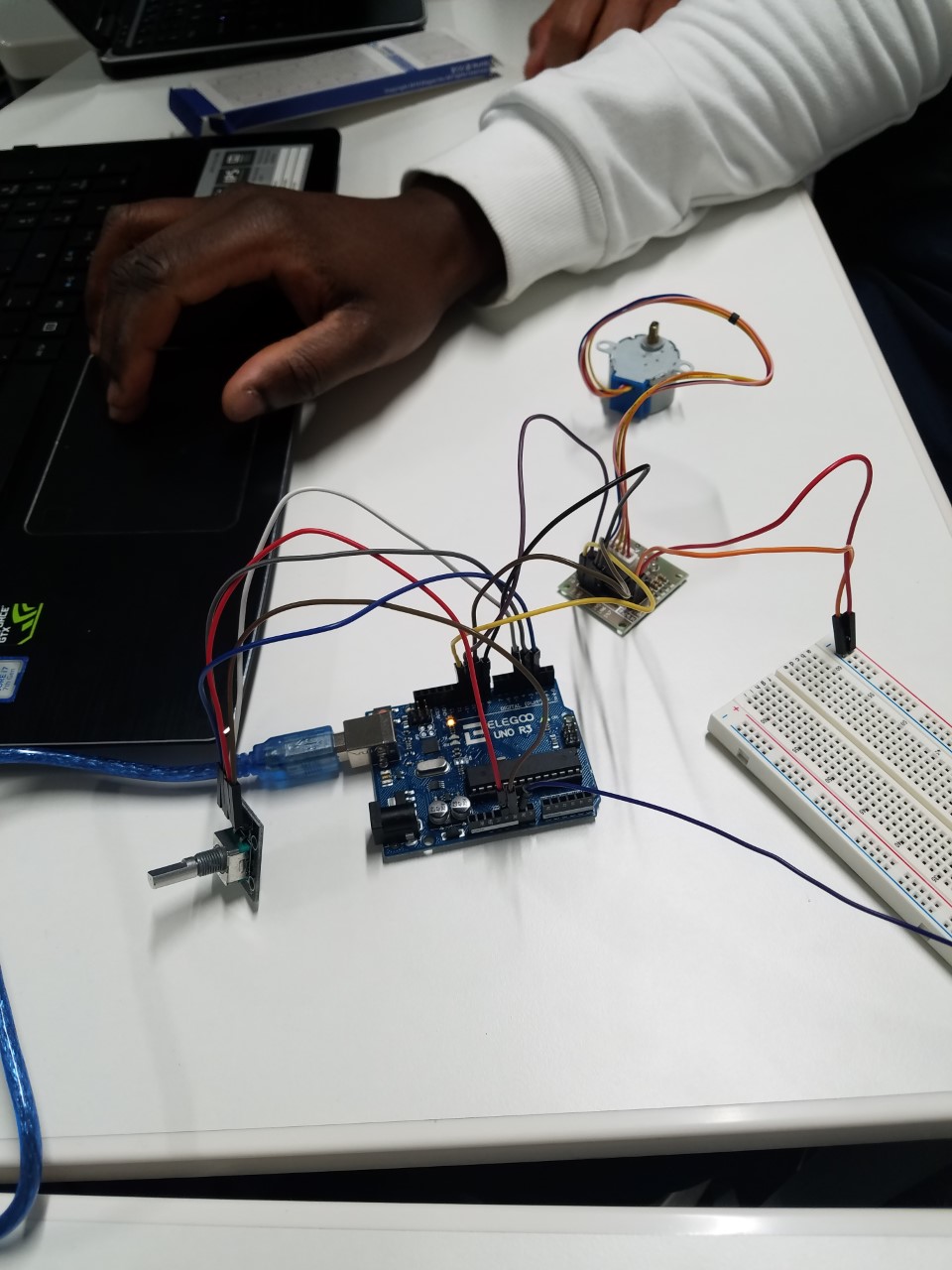

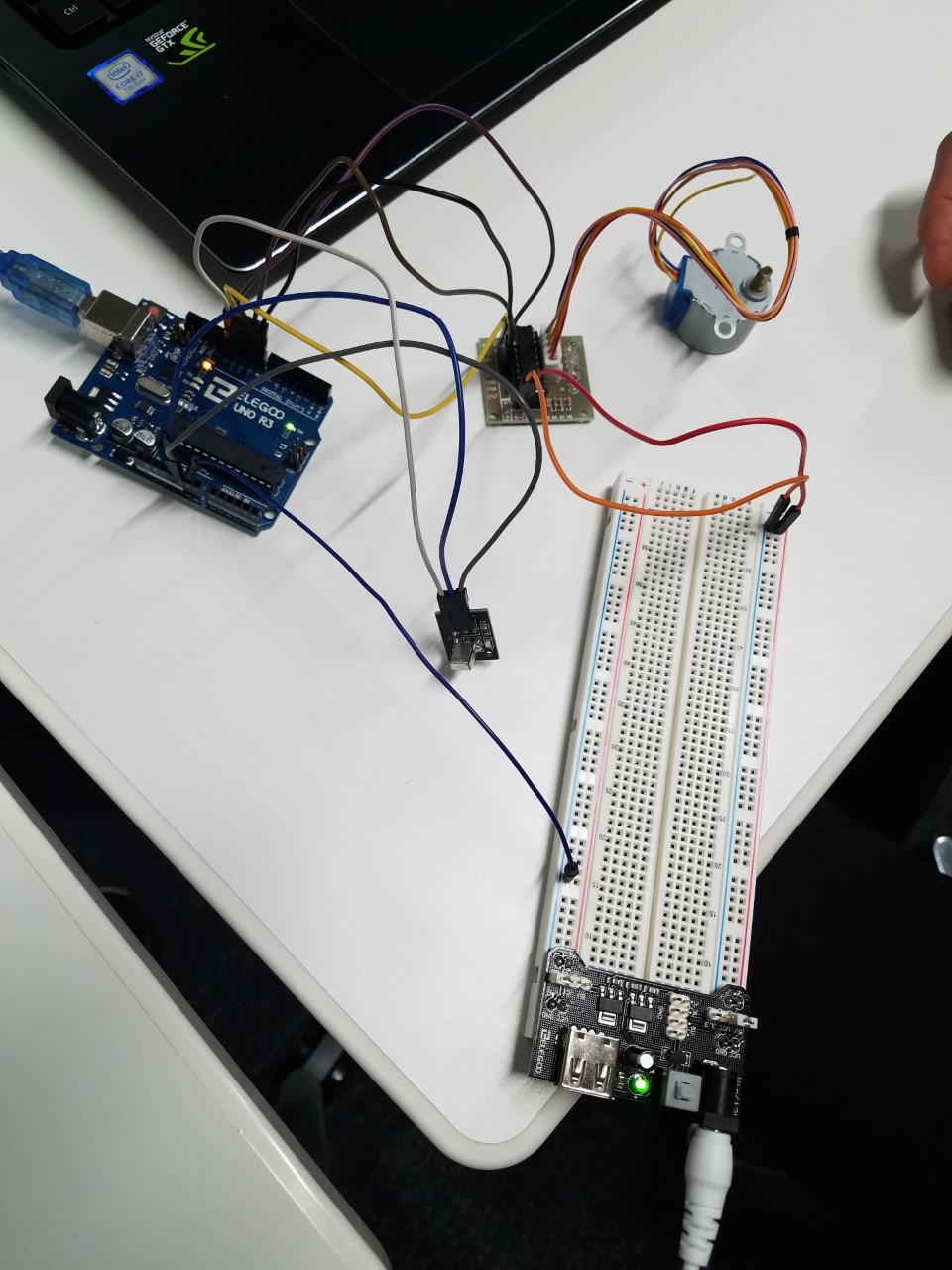

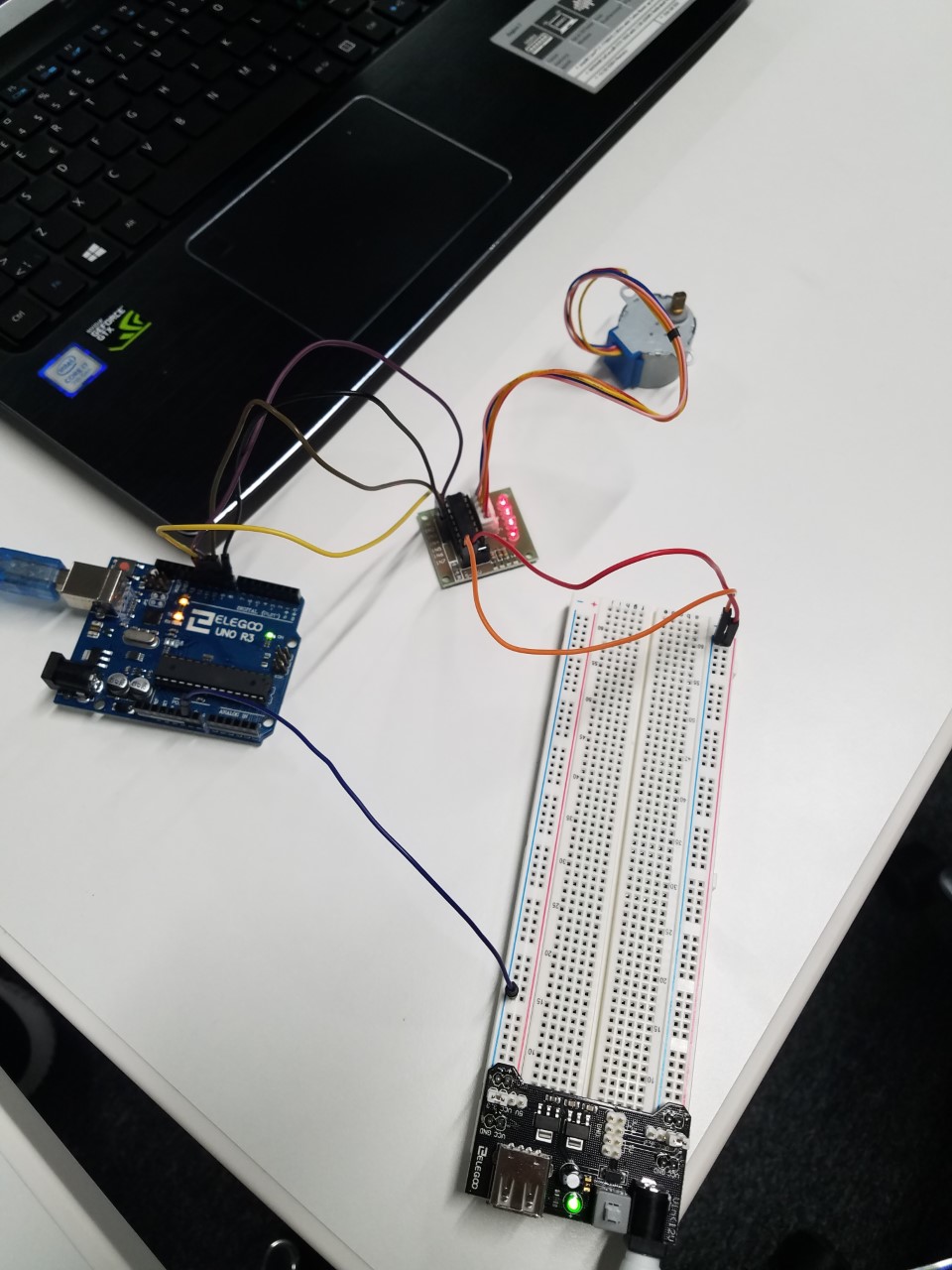

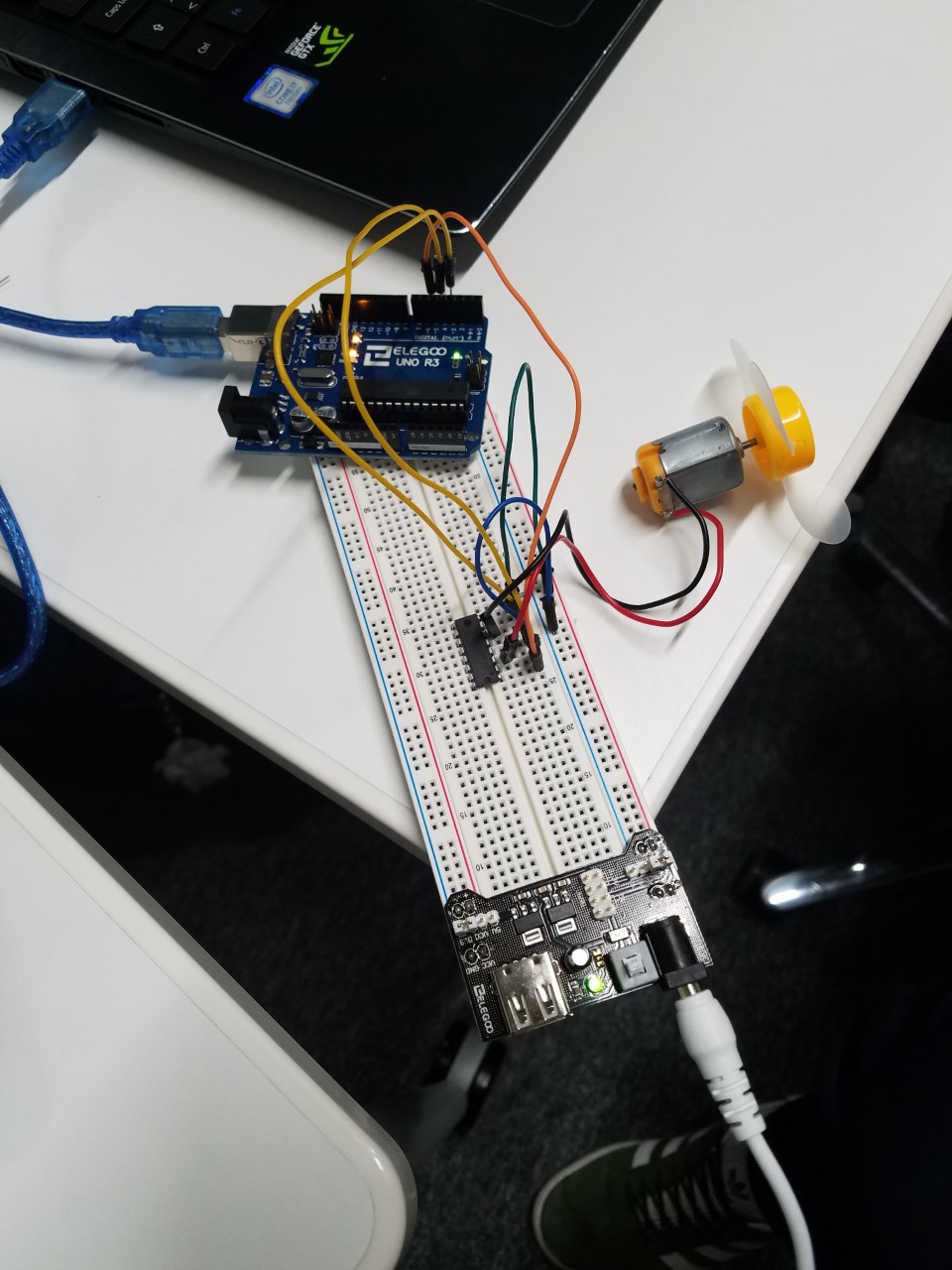

Finally, the servo motor is the most essential component of the Feeder system. It is critical to the success of the project. The main objective of the servo is to rotate at a 60 degree angle to open a tray that dispenses a measured quantity of food when the sensor in activated. As described earlier the sensor is deactivated after the initial dispense to avoid multiple dispensation. It is a very responsive motor and it is efficient in activating a dispense.